Reasons and steps for PCB cleaning

- 8月 22, 2017

- 11:29 下午

If PCB is not properly cleaned, certain materials used in PCB assembly or modification can lead to serious circuit functional problems.One of the most common problems of this kind is the flux.

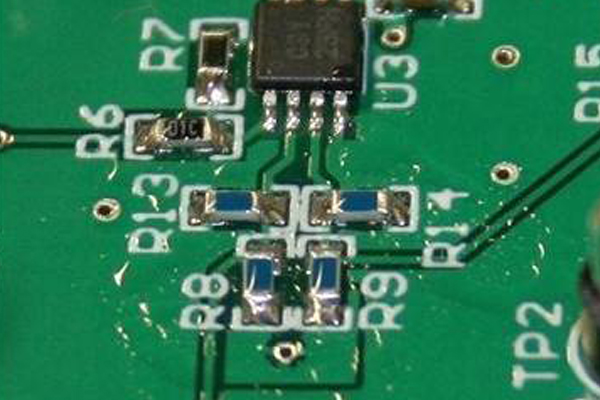

Figure 1 is the PCB with too much flux.

Flux is a chemical used to assist in welding components to PCB.However, it is regrettable that if it is not removed after welding, the flux will degrade the surface insulation resistance of the PCB, which will cause serious degradation of the circuit performance in the process.

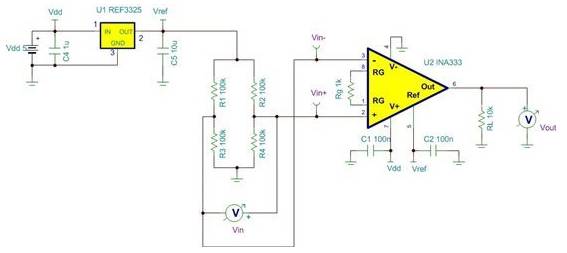

FIG. 2 is a test circuit used to show the results of flux contamination.The bridge network can simulate high impedance bridge sensor with a voltage of 2.5 V reference voltage.The differential bridge sensor outputs VIN – VIN – can connect to the gain of 101V/V INA333.Ideally, the bridge is in equilibrium, so VIN – VIN – = 0V.However, the flux pollution will cause the actual bridge sensor voltage to drift away over time.

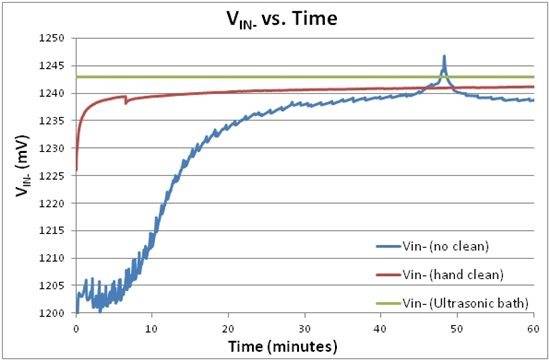

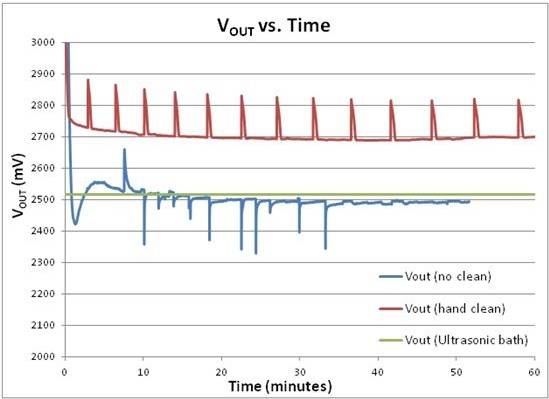

In this test, after the assembly, we also recorded the changes of VIN – and VOUT after a different degree of cleaning.

Not clean;

Manual cleaning, air drying;

Ultrasonic cleaning, drying, baking.

As can be seen from figure 3, the flux pollution has a serious effect on the output performance of the bridge sensor.In the case of uncleaned or manual cleaning, the bridge sensor voltage never reached the expected voltage of about VREF / 2, even after an hour of stabilization.In addition, the uncleaned circuit board also shows a large amount of external noise collection.After using ultrasonic bath cleaning and completely drying, the bridge sensor voltage is steady like a rock.。

Looking at the output voltage of INA333, we will continuously see the performance degradation caused by improper cleaning.The uncleaned circuit boards appear with DC errors, excessive length stabilization time, and severe external noise collection;Strange, extremely low frequency noise occurs on the manually cleaned circuit boards.The root cause is the air conditioning cycle inside the test facility!

As expected, the circuit boards that were properly cleaned and dried were performing well, and none of the points in the test shifted.

In summary, improper flux cleaning can cause serious performance degradation, especially in high-precision DC circuits.For any PCB that has been manually assembled or modified, be sure to use an ultrasonic bath (or similar method) to complete the final cleaning.After the air compressor is air-dried, a slightly higher temperature is used to bake the assembly and clean the PCB, which can remove any residual moisture.We’re typically at 70 & deg;C bake for 10 minutes.

This simple “keep clean” technique should help you drastically reduce the time spent on troubleshooting, and help you spend more time designing excellent, high-precision circuits!

This content is from the network, for exchange and study only, please do not use for commercial use, if it involves copyright issue please contact us to change and delete in time!